Introduction

Explore the essential world of drilling rig components. From crown blocks to Accumulator. Learn about the drilling rig components and machinery that power the oil and gas industry.

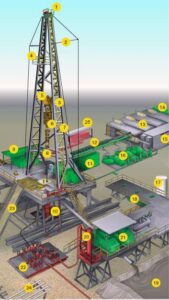

Basic drilling rig components

Drilling rig components: 1. Crown block:

The crown block is an important part of the drilling rig components. Located near the top of the derrick or mast it plays an important role in supporting the drilling line and ensuring its proper alignment during the drilling process. This component helps maintain tension on the drilling line which is necessary to raise and lower the drilling tools and drill string into the wellbore. A crown block usually consists of multiple pulley sheaves which guide the drilling line and reduce friction. By effectively distributing the weight of the drilling equipment the crown block contributes to a safe and efficient drilling operation.

2. Hoist line:

The hoisting line is an important component of the hoisting system of the drilling rig. It is a strong cable or wire rope designed to handle heavy loads such as drill string, tools and other equipment during drilling operations. The hoist line is wound around the drum of the drawworks, which is powered by the rig’s engines. As the drawworks turns it increases or decreases the hoist line and the associated load.

you may read introduction to directional drilling

This drilling rig component is important for controlling and manipulating the drilling equipment’s depth and position within the wellbore. It plays a key role in the drilling process by allowing the drilling crew to lower the drill string into the well during drilling and safely retrieve it when needed. Strong and durable the hoist line is an essential element to ensure efficient and safe operation of the drilling rig.

3. Drilling line:

Drilling line is a critical component in the drilling process, ensuring the safe and efficient movement of equipment within the wellbore, and is engineered to handle the demanding conditions of drilling operations.

4. Monkey-board:

Monkey-board refers to a platform or working area located on the derrick or mast of a drilling rig. Derrickmen who are part of the drilling crew, use the monkey-board to perform various tasks during the drilling process. The monkey-board located at various heights on the derrick depends on the rig design and specific drilling requirements. The derrickman is usually responsible for handling and guiding the drill pipe, drill collar, and other components of the drill string.

5. Travelling block:

The traveling block is an important component in the hoisting system of a drilling rig. Located inside the derrick or mast it is responsible for supporting and controlling the movement of the drill string during drilling operations. This heavy duty block is equipped with sheaves or pulleys through which the drilling line passes. The main function of the traveling block is to facilitate the lifting and lowering of the drill string, drill collars and other downhole tools in and out of the wellbore. It plays a key role in maintaining tension on the drilling line and ensuring that equipment is raised and lowered safely and efficiently.

6. Top Drive system (TDS):

Top drive system is a important part of drilling rig components used in modern drilling operations, particularly in oil and gas exploration. It replaces the traditional kelly and rotary table and provides several advantages: Rotation: A top drive system rotates the drill string, including the drill pipe and drill bit, over the derrick or mast. This allows continuous drilling without the need to trip out the entire drill string to change the bit. Torque: It can provide high levels of torque to the drill string, enabling efficient drilling of deep and difficult wells. Safety: Top drive systems improve safety by reducing manual handling of heavy drilling equipment and reducing the risk of accidents. Drilling efficiency: They increase drilling efficiency and improve quality, making them the preferred choice for many drilling operations.

7. Mast:

A mast in drilling rig refers to a tall, vertical structure that provides structural support for various drilling rig components and equipment used in drilling operations. It is a fundamental part of the rig’s overall structure and performs several important functions: Support: Provides a stable platform for mounting essential equipment such as the mast derrick, top drive system, traveling block, crown block, and drilling line. . Height: Masts are usually very tall structures, and their height is important to accommodate the length of the drill string and to allow drilling to significant depths. Rigidity: Masts are designed to withstand the various forces and vibrations associated with drilling, ensuring rig stability during operation. Accessibility: These often include platforms and walkways to allow workers to safely access different levels of drilling equipment. Hoisting: Masts are an integral part of the hoisting system, providing a vertical path for raising and lowering the drill string and other drilling tools in and out of the wellbore.

8. Drill pipe:

Drill pipe is an important part of a drilling rig components used in the oil and gas industry. It is a tubular steel pipe with threaded connections at both ends, designed to transfer drilling fluid, rotational torque, and equipment from the surface down the wellbore to the drill bit.

9. Doghouse:

It serves as a workspace and storage area for various tools, equipment and supplies required during drilling operations.

10. Blowout preventer (BOP):

A blowout preventer is an important safety device used in the oil and gas industry, especially during drilling operations. BOPs are designed to prevent the uncontrolled release of oil or gas from a well.

11. Water tank:

Water tanks play an important role in supporting the drilling process by providing the necessary water for drilling fluid preparation, equipment cooling, and other operational needs, contributing to the efficiency and safety of drilling activities.

12. Electric cable tray:

Electric cable trays play an important role in maintaining electrical infrastructure on drilling rigs, ensuring safe and reliable operation of equipment and systems involved in drilling operations.

13. Engine generator set:

Engine generator sets are an important drilling rig components providing the electrical power necessary to operate various equipment and systems, including drilling machinery, lighting, and control systems, enabling them to perform drilling operations in both onshore and offshore environments.

14. Fuel tanks:

Fuel tanks on oil and gas drilling rigs are containers used to store the fuel needed to power various equipment and machinery on the rig.

15. Electric control house:

Electric control houses are an important part of drilling rig components, centralizing the management of electrical and control systems to ensure the safe and efficient operation of rig equipment. They are designed to withstand harsh environmental conditions and maintain the reliability of electrical and control systems essential during drilling operations.

16. Mud pump:

It is use in the drilling process by circulating the drilling fluid commonly known as drilling mud in the wellbore.

17. Bulk Mud Components Storage:

It involves the systematic and safe storage of various components and materials that are used to prepare drilling mud.

18. Mud pits:

These constructed pits are used to store, treat and manage drilling mud.

19. Reserve pits:

Reserve pits also called reserve mud pits or reserve drilling mud pits are a specific type of pit used in drilling operations in the oil and gas industry. These pits play a temporary and back-up role in the management of drilling mud and waste material.

20. Mud gas separator:

Its primary function is to separate and safely extract gas primarily hydrocarbons from the drilling mud to prevent potentially hazardous situations.

21. Shale shakers:

It is designed to separate solids, such as cuttings and debris, from drilling mud, ensuring that the mud can be efficiently reused.

22. Choke manifold:

It is designed to control the flow of drilling fluids, primarily during drilling operations and in response to well control situations.

23. Pipe ramp:

It refers to a structure or inclined platform designed to facilitate the movement of pipes, tubulars and other equipment between different levels of the rig.

24. Pipe racks:

Designed to support and manage a network of pipes and tubing.

25. Accumulator:

An accumulator is a special device designed to store and deliver hydraulic fluid under high pressure.

Best drilling rig components manufacturer

https://www.environmental-expert.com/companies/massenza-drilling-rig-79298

Good explanation