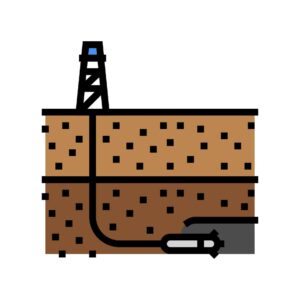

Introduction to Directional Drilling

Definition:

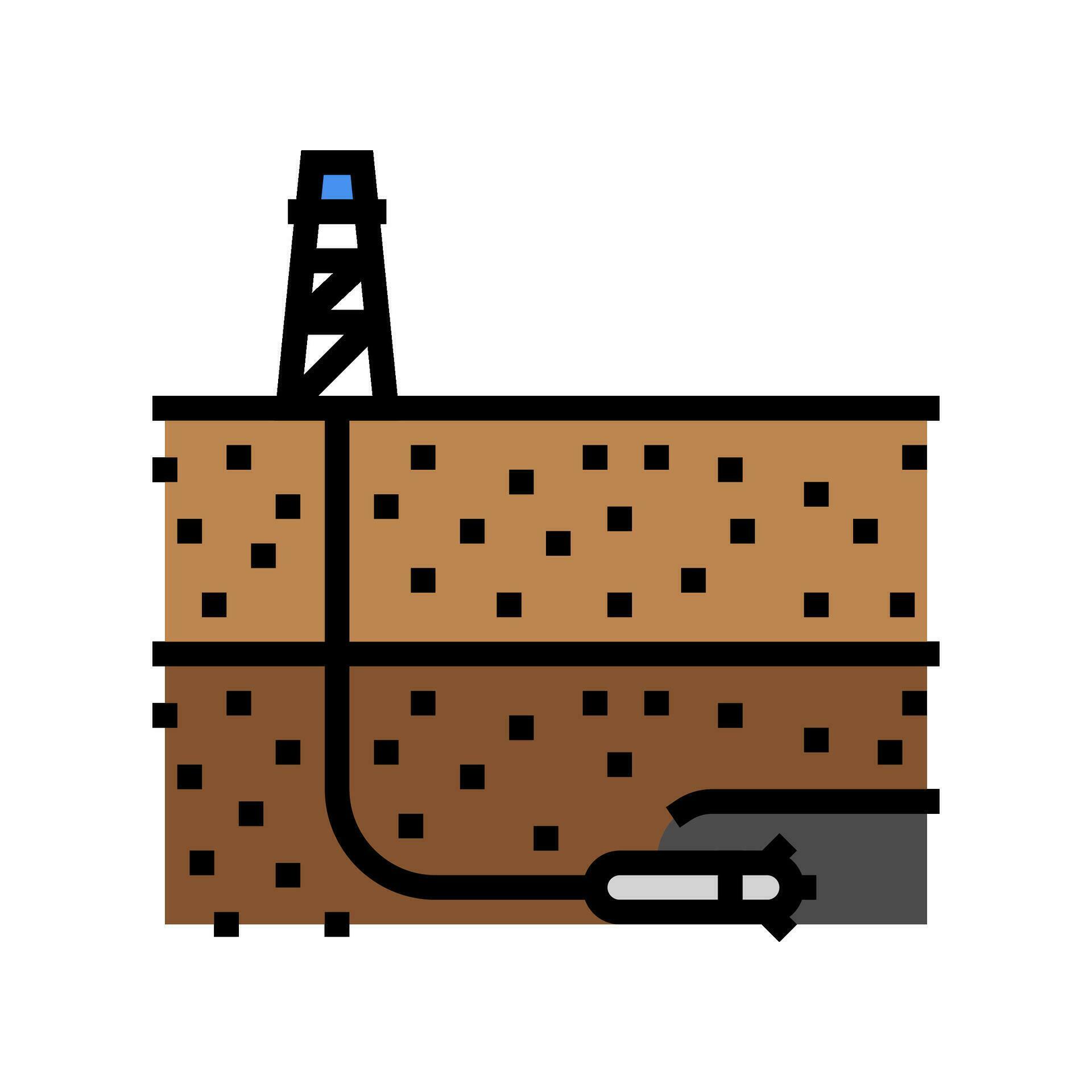

Directional drilling is a sophisticated drilling technique that allows engineers and drillers to control the path of a borehole, guiding it in a specific direction or speed. This method is used to reach targets that cannot be accessed by conventional vertical drilling techniques. Directional drilling involves adjusting the angle and azimuth (direction) of the wellbore to pass through complex geological formations and reach precise subsurface locations.

Significance and applications

Significance:

The importance of directional drilling is evident in several important aspects:

1. Access to previously inaccessible resources:

Directional drilling has revolutionized the oil and gas industry by providing access to deposits that were once considered inaccessible. . It allows the extraction of hydrocarbons from offshore and unconventional reservoirs, maximizing resource recovery.

2. Cost savings:

In construction and utilities, directional drilling reduces the need for disruptive excavation. This leads to substantial cost savings as it reduces surface disturbance, maintenance costs and project delays.

Application:

Directional drilling plays an important role in various aspects of the oil and gas industry:

1. Offshore exploration:

It is indispensable for drilling offshore wells, where precise direction of the well is required to access the underwater reservoirs. Control is required. Directional drilling allows operators to safely and efficiently access these valuable resources.

2. Unconventional Reservoirs:

In the realm of unconventional resources like shale gas and tight oil, directional drilling is the method of choice. It facilitates horizontal drilling through these resource-rich formations, unlocking vast energy reserves.

3. Reservoir Optimization:

Directional drilling is used to maximize the potential of existing reservoirs. By connecting multiple reservoir zones horizontally, it improves the flow of hydrocarbons and increases the overall production rate.

Historical perspective

Early beginning:

Directional drilling has its roots in ancient times when human ingenuity and resources were already in play. Early civilizations, including the Chinese and Persians, recognized the advantages of digging wells at angles to gain access to more water sources. These early methods laid the foundation for what would later become a sophisticated and indispensable drilling technique.

Milestones in Directional Drilling:

Spindle Top: Birth of Directional Drilling (1901)

The beginning of directional drilling as we know it today can be traced to the Spindle Top oil field in Texas. In 1901, a historic gusher erupted at Spindle Top, starting the Texas oil boom. Drillers faced challenges as they tried to control the gusher, which led to the development of early directional drilling techniques to regain control of directional wells.

A dictionary of oil & gas industry

The Steerable Motor (1920s):

The 1920s saw significant advances in directional drilling with the invention of the steerable motor. This innovation allowed drillers to control the direction of the drill bit, making it possible to drill horizontally or at certain angles, greatly increasing the chances of a good placement.

World War II and the MWD Revolution (1940):

World War II accelerated the development of directional drilling technologies. During this time, the concept of Measured While Drilling (MWD) was born. MWD tools enabled drillers to obtain real-time data from downhole, improving accuracy and control of steering wheels.

Ocean and Deepwater Exploration (1960s – 1970s):

As offshore drilling activities expanded in the 1960s and 1970s, directional drilling became indispensable. Drillers were tasked with accessing underwater reservoirs beneath the ocean floor, where precise control over the direction of the well was paramount.

Horizontal Drilling Revolution (1980 – 1990):

The 1980s and 1990s witnessed a horizontal drilling revolution, driven by advances in directional drilling techniques. This allowed for more efficient extraction of oil and gas from reservoirs, especially in unconventional formations such as shale.

Advanced Technologies and Automation (21st Century):

In the 21st century, directional drilling entered a new era with advanced technologies such as rotary steerable systems and autonomous drilling. These innovations continue to increase accuracy and efficiency, enabling drillers to navigate complex geological formations with exceptional precision.

Challenges in Directional Drilling

Geological Considerations

Directional drilling in the oil and gas industry is not without its geological challenges:

Complex reservoirs:

Oil and gas reservoirs can be extremely complex with irregular shapes and different rock formations. Navigating through these formations while maintaining well integrity requires careful planning and skill.

Formation Stability:

Drilling through various geological formations can cause stability problems. Some formations may be prone to collapse, while others may contain abrasive material that can erode drilling equipment.

Loss of Circulation:

In some geologic conditions, drilling fluid may escape into porous formations, causing loss of circulation. This can inhibit drilling progress and create challenges for well control.

Equipment and Technology

The tools and technology used in directional drilling face unique demands in the oil and gas sector:

Advanced tools:

Directional drilling relies on specialized tools and equipment, including measurement-while-drilling (MWD) and logging-well drilling (LWD) system. Keeping these tools in top working order is essential for precise positioning.

High Pressure Environments:

Drilling in deep water or high pressure reservoirs requires equipment that can withstand extreme conditions. Ensuring reliability

Automation and Control:

With the increasing complexity of drilling operations, automation and control systems are essential for real-time decision making. Maintaining and upgrading these systems requires constant attention.

You may also read about drilling rig components

Safety concerns

Safety is paramount in oil and gas directional drilling due to the high-risk nature of the industry:

Well Control:

Maintaining control over the well is essential. Loss of control can lead to explosions, environmental damage, and safety hazards. Strict safety protocols and well control measures are essential.

Environmental Impacts:

Directional drilling often occurs in environmentally sensitive areas, such as offshore areas. Preventing oil spills and reducing environmental impact are constant safety concerns.

Worker Safety:

Operation of the drilling rig and associated equipment poses hazards to personnel. It is important to ensure worker safety through training and adherence to safety standards.

Regulatory Compliance:

Compliance with strict industry regulations and safety standards is non-negotiable. Navigating the regulatory landscape is an ongoing challenge.

Emerging Trends and Technologies in Directional Drilling

Advances in Drilling Technology

The oil and gas industry is constantly evolving, and emerging trends and technologies are playing an important role:

Digitization and data analytics:

The industry is increasingly using data analytics and digital tools to improve drilling operations. Real-time data analysis helps make informed decisions and improve drilling efficiency.

Machine learning and AI:

Machine learning and artificial intelligence are being used to predict drilling problems, optimize drilling parameters and increase wellbore placement accuracy.

Automated Drilling Systems:

Automated drilling systems, including rotary steerable systems and autonomous drilling rigs, are becoming more popular. These systems provide precise control and minimize human intervention.

Sustainable Practices

Sustainability is a growing concern in the oil and gas sector, and innovative practices are emerging:

Minimizing environmental impact:

Operators are adopting methods to minimize the environmental impact of drilling operations. This includes using biodegradable drilling fluids and reducing emissions.

Efficient use of resources:

Sustainable drilling involves efficient use of resources. Energy-efficient drilling techniques are gaining in importance, along with water recycling and reuse.

Wellbore Integrity:

Ensuring the integrity of wellbores is critical to prevent leaks and environmental contamination. Advanced cementing techniques and well monitoring systems enhance well integrity.

Carbon Capture and Storage (CCS):

The industry is exploring CCS technologies to capture and store carbon emissions from drilling operations, thereby reducing greenhouse gas emissions.

Conclusion

Finally, directional drilling has emerged as a cornerstone of the oil and gas industry, revolutionizing the way we access and extract our precious hydrocarbon resources. This drilling technique, which allows precise control of the well path, has a rich historical background and a promising future driven by modern technologies and sustainable practices.

Recap of Key Takeaways

Throughout this journey into the world of directional drilling, we have discovered several key takeaways:

Precision in Exploration:

Directional drilling enables precise targeting of oil and gas reservoirs, unlocking previously inaccessible resources and maximizing recovery.

Challenges and Solutions:

We explore the geologic challenges, equipment requirements, and safety concerns associated with directional drilling, along with the technological advances that address them.

Emerging Trends:

The industry is witnessing change with emerging trends such as digitization, artificial intelligence, and sustainability practices reshaping drilling operations.

Importance of understanding Directional Drilling

Understanding directional drilling is not just a matter of industry knowledge. It is a window into the future of energy exploration and responsible resource management. Whether you’re an industry professional, investor, or just someone curious about the processes that power our world, understanding the complexities of directional drilling is important. Additionally, as we navigate an era of growing environmental awareness, learning how industry is adopting sustainable practices underscores the importance of responsible resource development. Directional drilling, with its ability to efficiently access reservoirs and reduce environmental impact, plays a critical role in this transition.

1 thought on “Directional Drilling”